I Need Global

Çok kültürlü ihracat tecrübemiz ve küresel lojistik ağımızla ithalat ve ihracatta güvenilir çözüm ortağınızız.

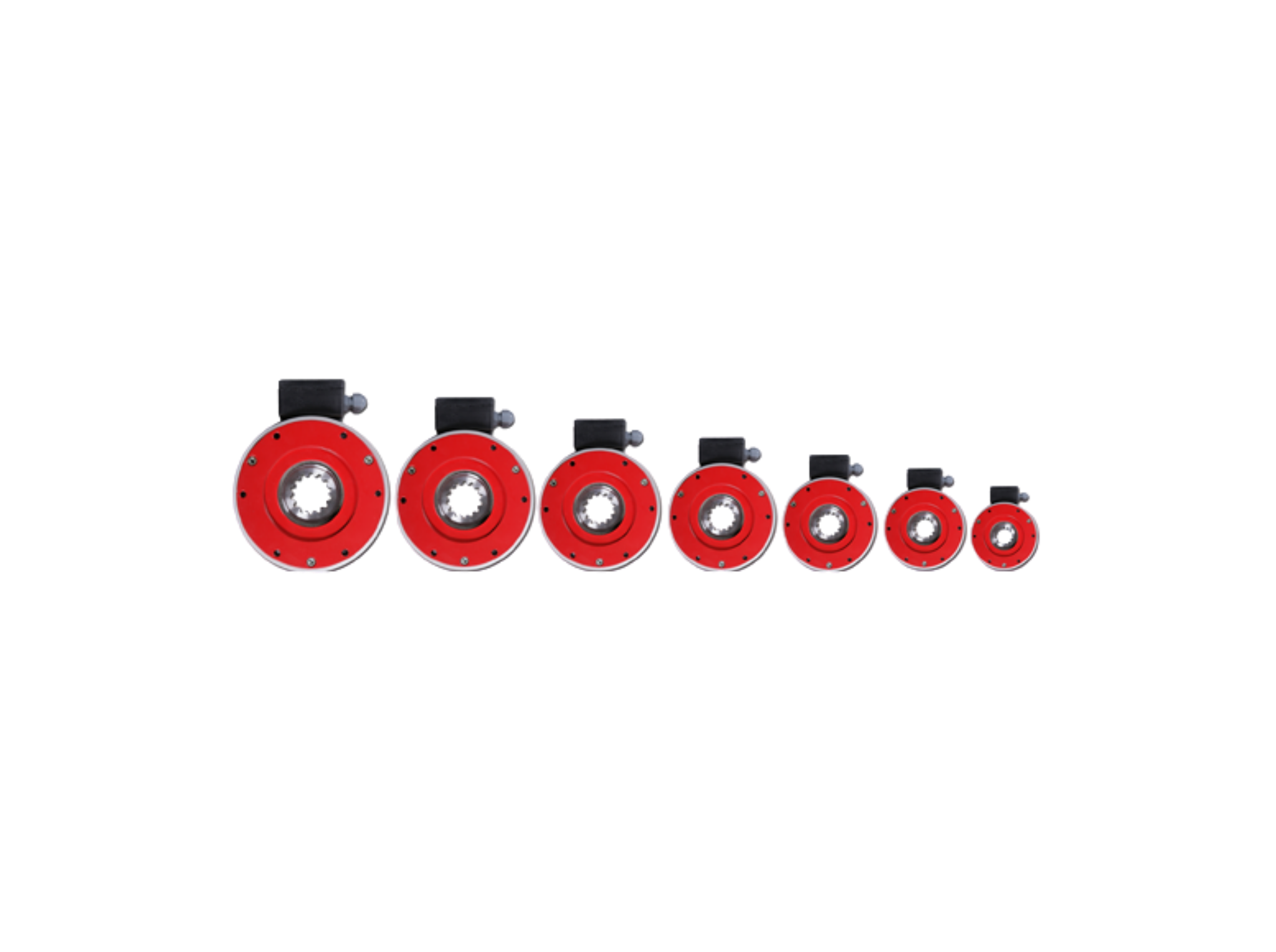

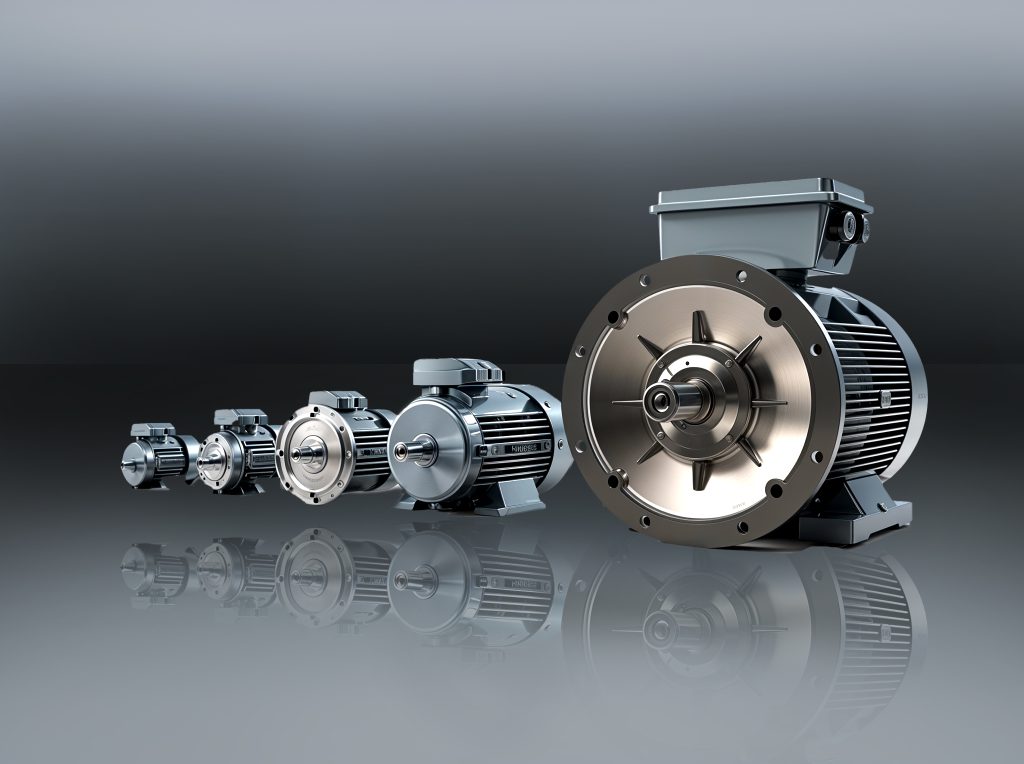

Electric Motors

1-Phase Asynchronous Motors

3-Phase Asynchronous Motors

Milking Machine Motors

WEG Special Motor Series

Ex-proof Motors

Special Production Motors and Parts

1-Phase Asynchronous Motors

The structure of 1-phase asynchronous motors consists of two main components: the stator and the rotor, similar to 3-phase asynchronous motors.

The stator forms the stationary part of the motor. The stator core and field windings are located in the stator.

1-phase asynchronous motor stators typically have two windings: the main winding and the auxiliary winding.

The rotor is the rotating part of the motor.

Wound-rotor asynchronous motors have windings in their rotors, while squirrel-cage asynchronous motors have short-circuited bars in their rotors.

1-phase asynchronous motors:

* Can be started Directly On Line (DOL) from the mains.

* Standard motors can only be used on 50Hz or 60Hz mains.

* Standard motors can be powered and operated from 220 V residential mains.

1-Phase Asynchronous Motors Product Brochure

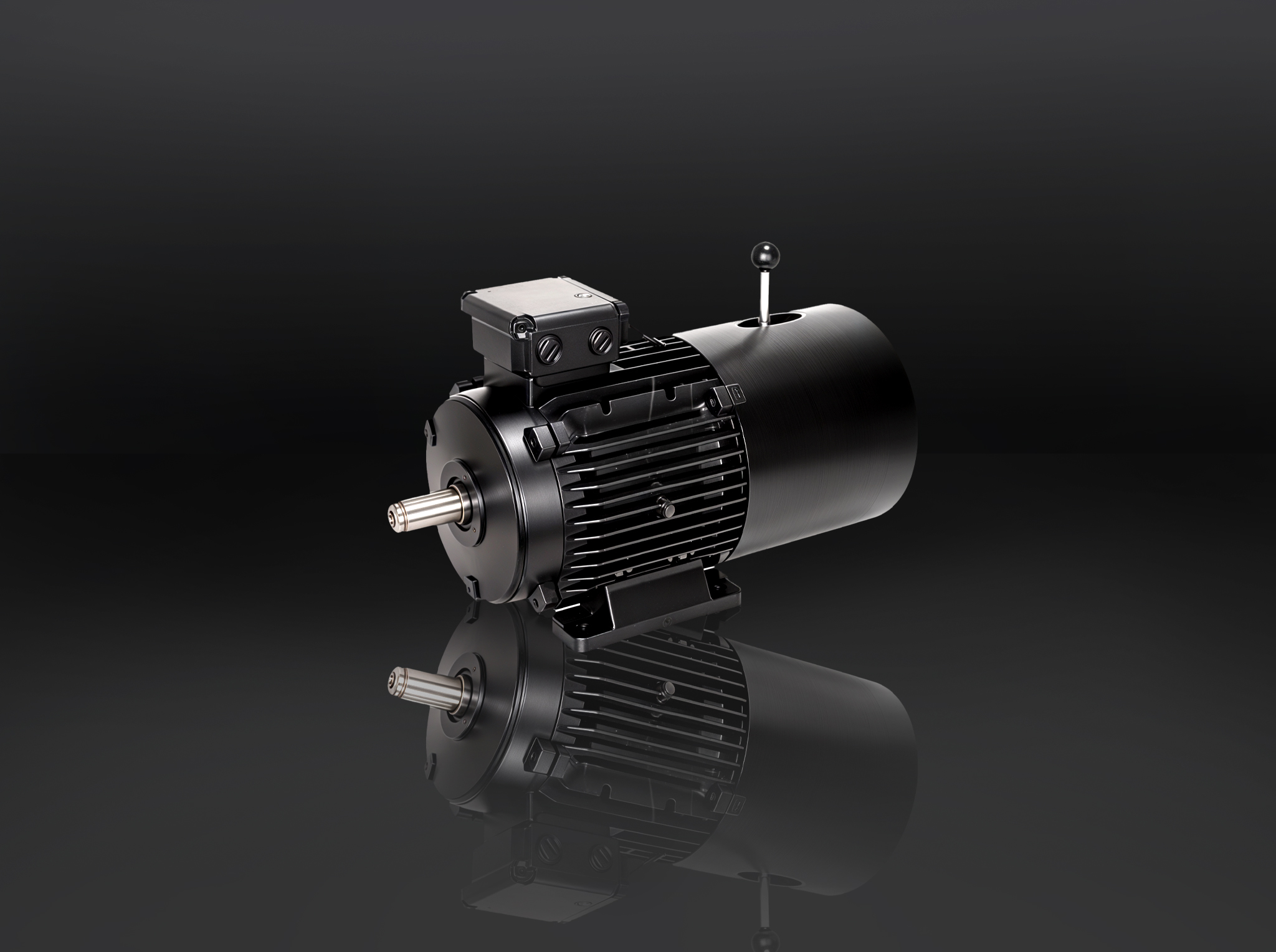

3-Phase Asynchronous Motors

3-phase asynchronous motors consist of two main components: the stator and the rotor.

The stator forms the stationary part of the motor. The stator core and field windings are located in the stator.

3-phase asynchronous motor stators have a separate winding for each of the three phases.

The rotor is the rotating part of the motor.

Wound-rotor asynchronous motors have windings in their rotors, while squirrel-cage asynchronous motors have short-circuited bars in their rotors.

The squirrel-cage asynchronous motor is the most common type of asynchronous motor used in industrial applications.

3-phase asynchronous motors:

* Can be started Directly On Line (DOL) from the mains. Speed control is not possible in this case.

* Can be used by being powered with a Variable Frequency Drive (VFD) for speed control. Suitable for both scalar and vector control.

* The same motor can be used on both 50Hz and 60Hz mains.

* Suitable for Star/Delta starting or using a soft starter to limit the starting current.

3-Phase Asynchronous Motors Product Brochure

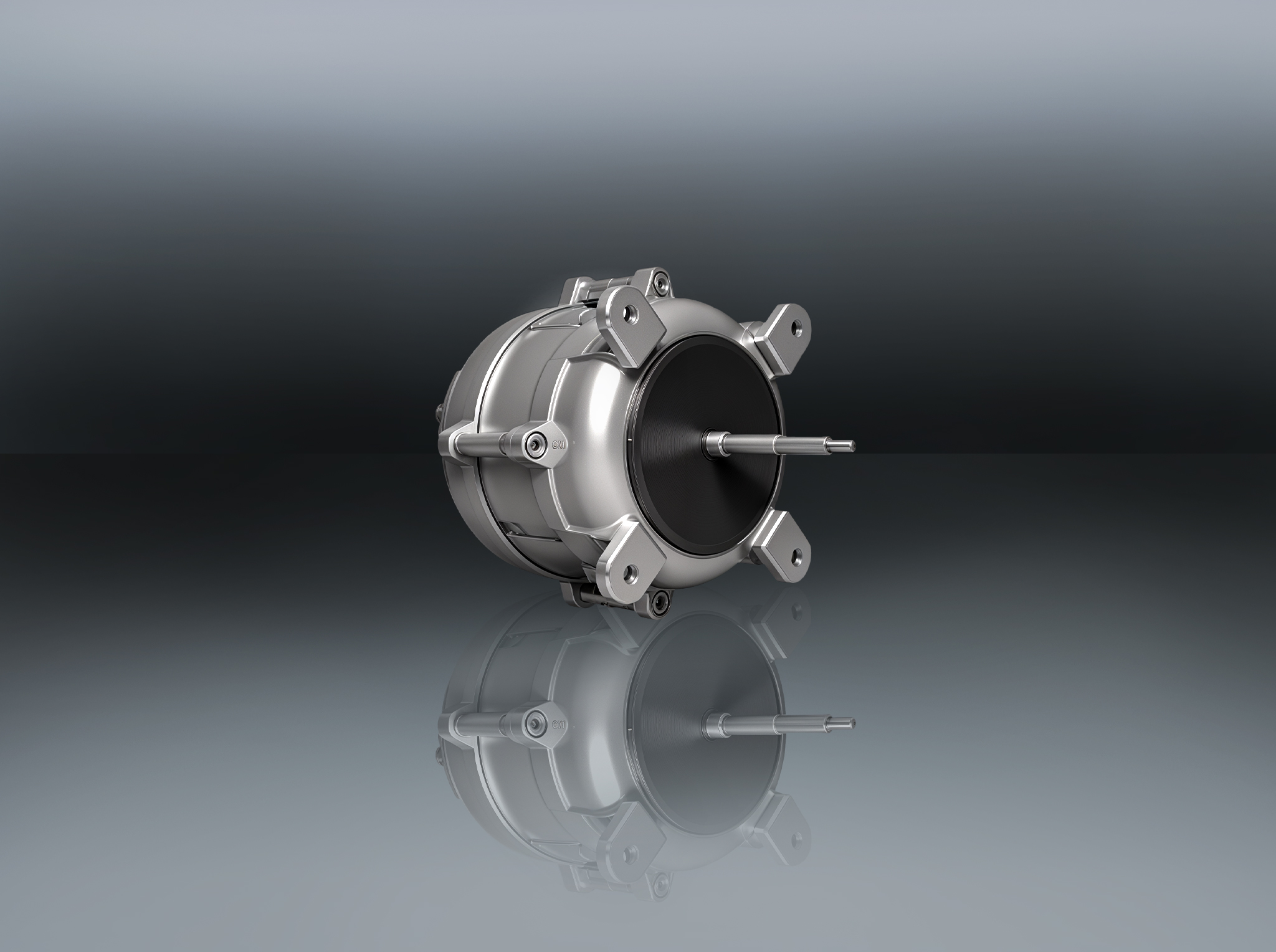

Milking Machine Motors

Milking machines, a vital component for efficient and hygienic milk production in modern animal husbandry, operate longer and more effectively with a high-quality motor.

Volt by WEG offers a powerful, silent, and reliable solution to farmers and livestock businesses with motors specially developed for milking systems.

Key Features:

* Silent and Vibration-Free Operation: Prevents stress in animals, increasing milking efficiency.

* Hygienic Design: Suitable for the milking environment, easy to clean, and safe structure.

* High Efficiency and Low Energy Consumption: Low-cost, uninterrupted performance for dozens of milkings per day.

* Durable Casing and Protection Class: Resilient to harsh agricultural conditions with its IP protection class and robust structure.

* Easy Installation: Compatible with all milking machines thanks to its compact and practical design.

* CE and ISO Certified: Compliant with international standards required in food production.

Milking Machine Motors Product Brochure

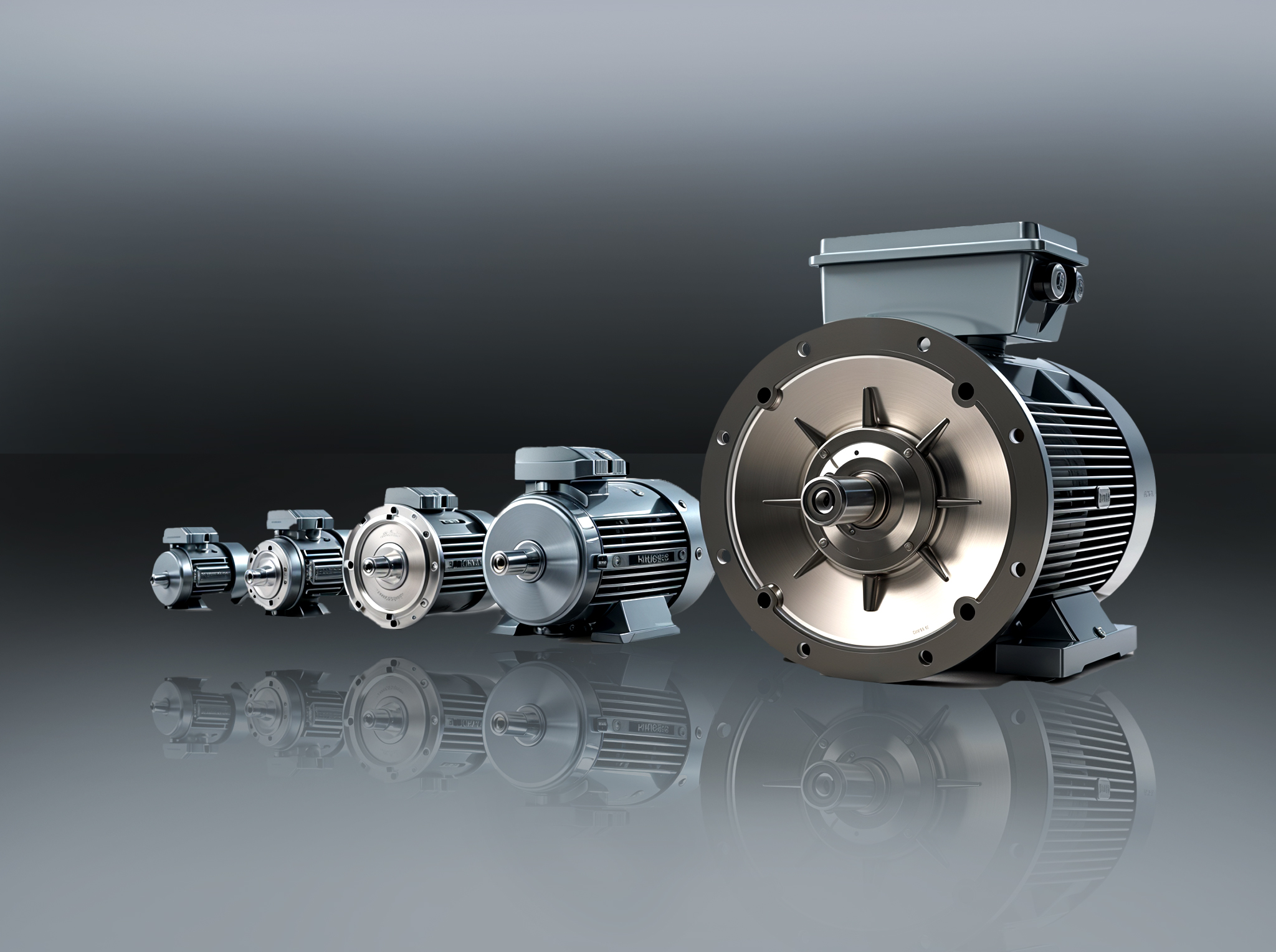

WEG Special Motor Series

By utilizing specially developed versions of standard 3-phase and 1-phase asynchronous motors (known as general-purpose motors) for specific applications, advantages in cost, performance, and quality can be achieved.

WEG Special Motor Series Product Brochure

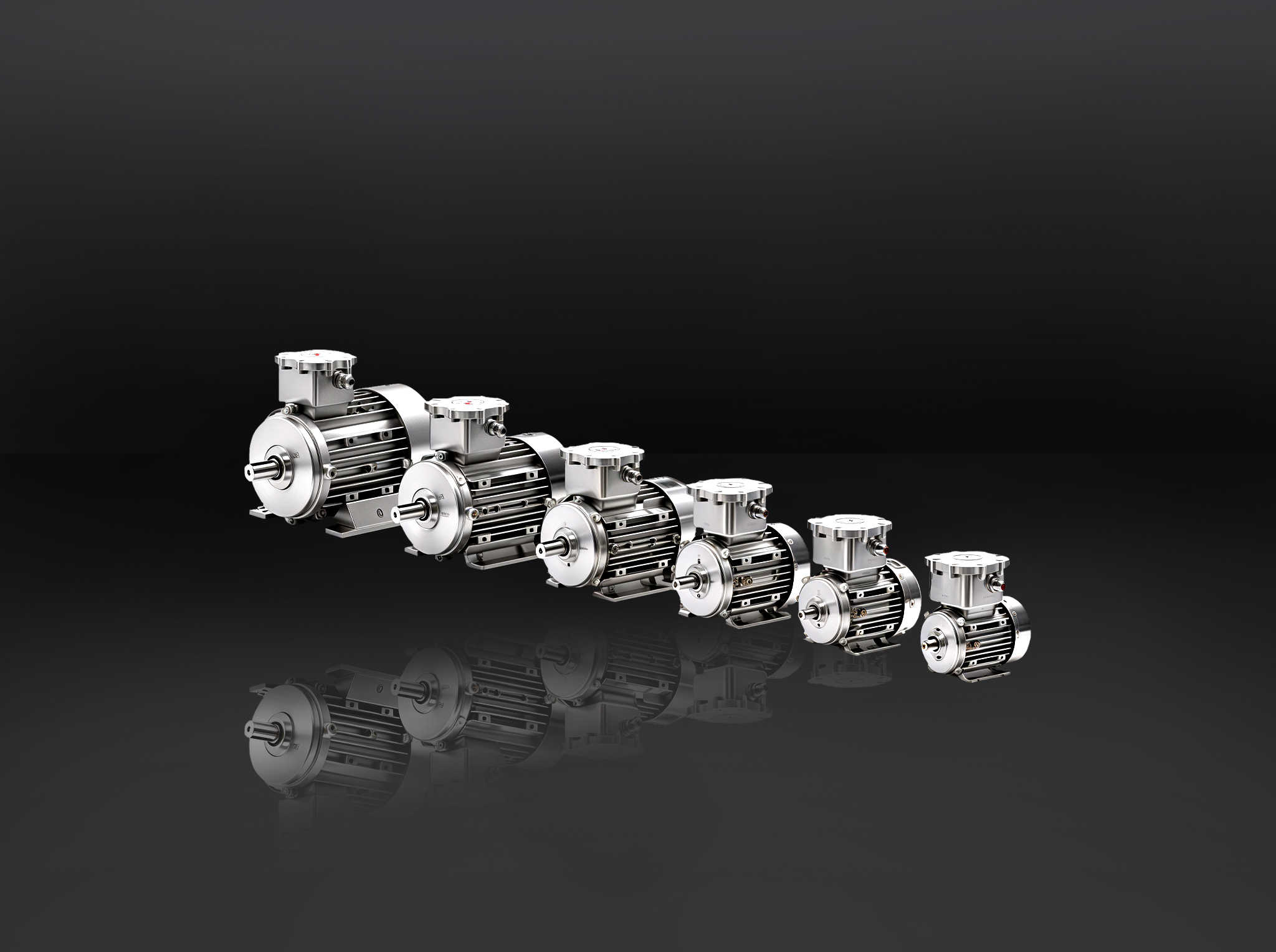

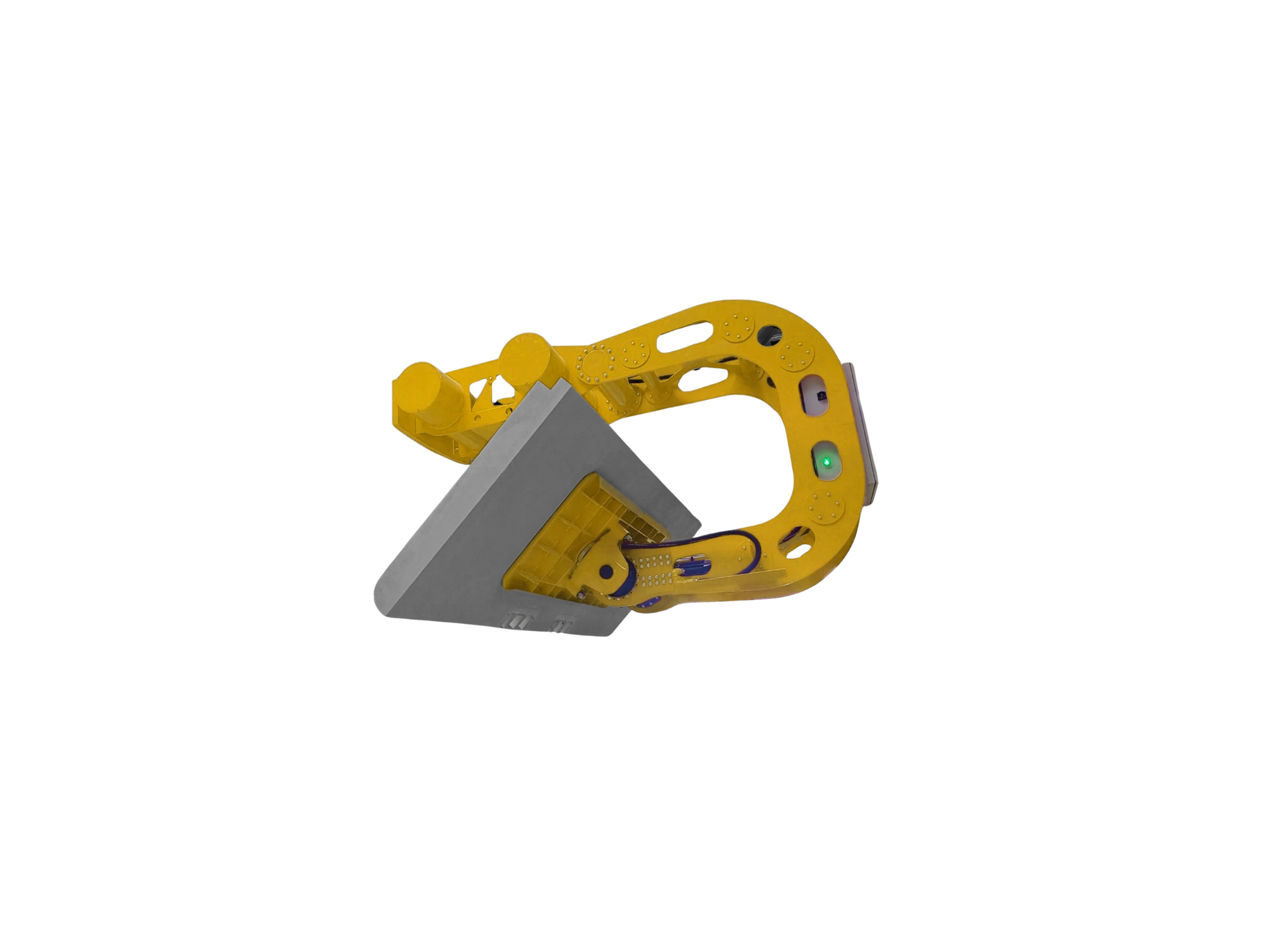

Ex-proof Motors

Ex-proof electric motors are designed to be resistant to gas or vapor explosions and to prevent sparks that may result from an explosion from contacting explosive gas or dust in the environment, which could cause an explosion or ignition.